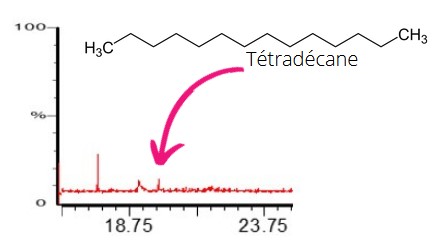

During the structural analysis by

GCMS traces of

tetradecane were noted, probably coming from aliphatic oils present during the design or transport of this insulator.

Regarding the

Pyrolyzer/GCMS analysis, we noticed a higher amount of

PDMS siloxane in the non-compliant sample, which would probably come from a silicone oil.

We also noted the presence of traces of

acrylic matrices , probably due to the presence of adhesives.

The nitrogen resistance test did not reveal any malfunction or degradation of the material.

EN

EN

FR

FR