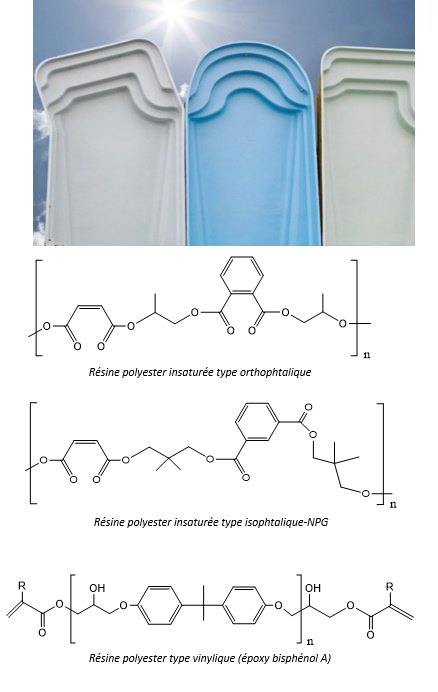

Types of resin:

The formulations of polyester resin ( gelcoat and resin for laminate) are very numerous and generally consist of an unsaturated polyester resin (orthophthalic, isophthalic, vinyl ester, etc.) crosslinked with a vinyl or unsaturated type compound (styrene, α-methyls¬ tyrene, vinyl toluene, divinylbenzene, DCPD, acrylic…). Not all of them can be used in a submerged environment and not all of them give the same final quality to the pool.

You will find quality resins at ECD, Napollon business park 13400 Aubagne France.

- Orthophthalic type unsaturated polyester resin

It is the most classic formulation for swimming pool shells, the least expensive, generally cross-linked with styrene, encountered in "entry-level" pools, which allows solid stratification but which suffers from great sensitivity to humidity. which compromises its durability (more frequent hydrolysis and osmosis). It also causes greater shrinkage when pulling parts from the mould.

- Isophthalic polyester resin

Isophthalic polyester resin is much less sensitive to hydrolysis than its orthophthalic counterpart. It is a low shrinkage resin which is used for good and very good quality pools.

The most efficient resin quality is obtained with a mixture of isophthalic polyester resin / NPG (Neopentylglycol) and vinyl (Epoxy BPA)

Due to their formulation, vinyl ester resins are halfway between polyesters and epoxies. The pre-polymer is obtained by reaction between methacrylic or acrylic acid on epoxy resins of the bisphenol A type. These resins have a good compromise between mechanical, chemical and cost properties and are among the very high quality resins for hulls. swimming pool (virtually no osmosis phenomenon). When mixed with isophthalic/NPG (Nepentylglycol) resins, they offer the most efficient gelcoats on the market.

EN

EN

FR

FR