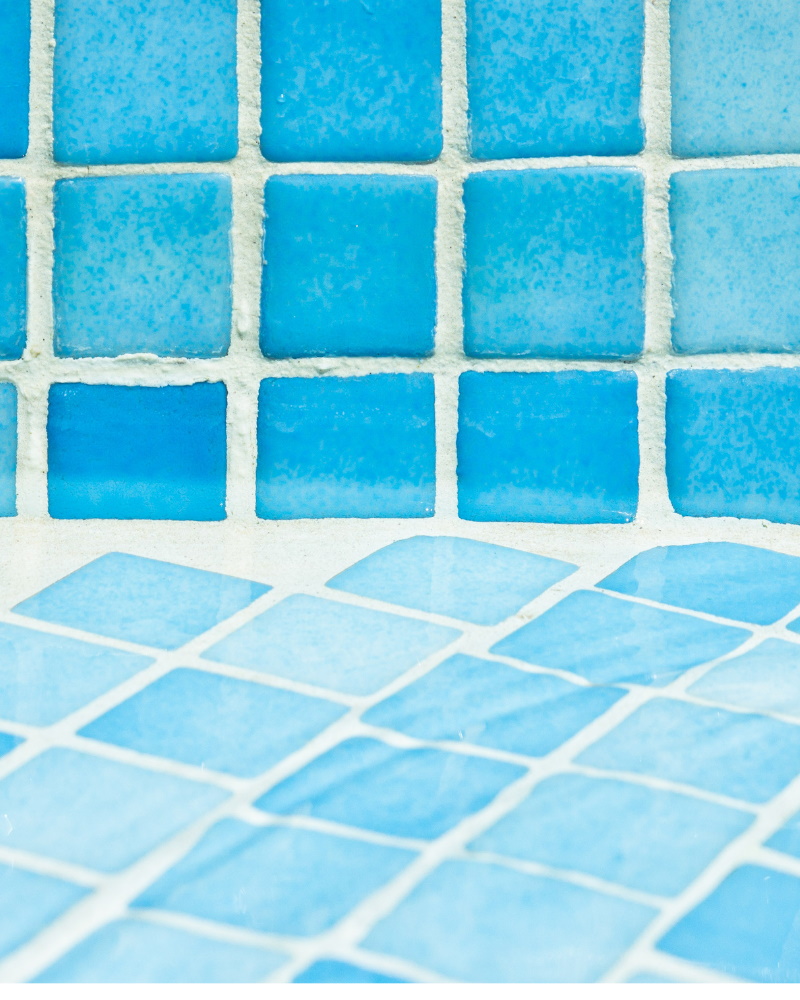

Analyzes on faulty mosaic pool joints

The joints of a tiling or mosaic in a swimming pool are the first defense against the infiltration of water in depth. Indeed, if the joints are defective, water will infiltrate between the tiling and its support causing their separation.

In addition to the art of installation, their chemical nature and therefore their mechanical property and their resistance to various aggressions (cleaning products, high pressure washing, water treatment, climatic conditions, etc.) is essential. They must be water-repellent and very resistant to be able to adapt to permanent immersion in water for several years, but also antibacterial, antifungal and anti-algae so as not to be the starting point for algae nesting.

The different products for making pool tile / mosaic joints

EN

EN

FR

FR